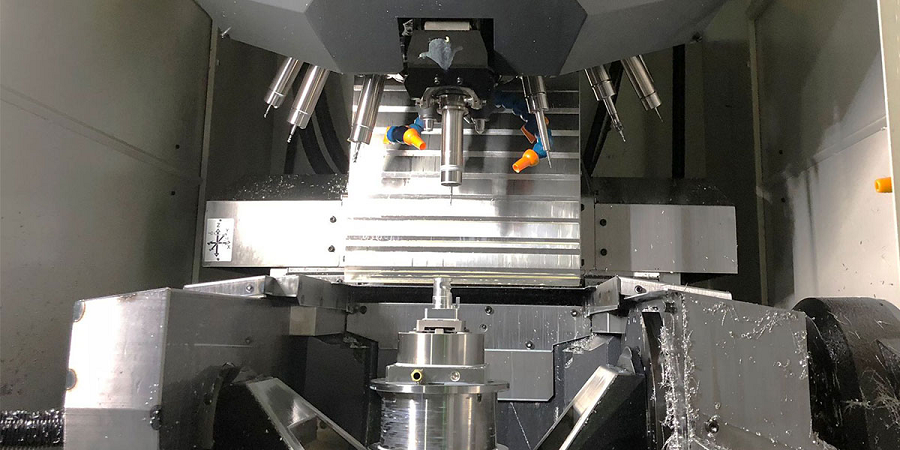

Many industries provide high-quality machining services including CNC lathe machining, wire EDM, 5 axis works, and more. They have huge experience producing complex components requiring tight tolerance, extraordinary accuracy for a multitude of industries, and high precision. Materials used in manufacturing of aircraft parts include aluminum, ceramic, bronze, brass, Nitronic, plastics, copper, structural and stainless steel, tantalum, titanium, etc. several products consist of actuators, heads, arms, bushings, housings, hinges, cams, panels, collects, pins, plates, connects, couplings, plugs and manifolds.

Why Do Aircraft Parts Need CNC Machining?

CNC machine makes plastic aircraft parts that are reliable, durable and lightweight. CNC Machining Aircraft Parts are subjected to harsh behavior from humidity and saltwater experience to quick thermal and air pressure changes and their parts have to be up to the challenge. An airplane is like a body in order for it works correctly, all the parts have to function well. A faulty or damaged part can lead to a breakdown of the whole system. Here are five areas in particular where CNC machining is important:

Engine:

As the heart of the aircraft, an engine supplies the mechanical power, which lets the plane to more. If an engine part fails, the plane could experience a sudden loss of power or a full mechanical breakdown. High-quality plastics provide high wear resistance and low friction. This offers them a long, reliable lifespan and lets them run dry should lubrication fail, increasing safety.

Avionics:

These electrical systems that include navigation, communication, and the display and management of various systems. That is the brain of an aircraft. These systems give crucial information to the pilot and must create reliability. Military-grade plastics can defend these systems from heat, electromagnetic interference, and corrosion.

Sensors:

A serious of receptors that collect information about the condition of the plane and outside of the world and relay that information to the brain. Without accurate data, pilots are flying blind. With CNC machined plastic parts, sensors can tolerate harsh military applications.

Airframe:

The airframe supports the aircraft. An airframe requires being strong but lightweight. High-end plastics provide high tensile and flexural strength on par with metal but a fraction of the weight decreasing the weight of the CNC Machining Aircraft Parts boosts speed and enhances fuel consumption.

Connectors:

In the body, everything is connecting together by muscles, joints, and ligaments. In an aircraft, this job is done by connectors. These parts must be flexible still durable enough to withstand constant environmental and mechanical stress.