Key Takeaways

- A reliable PCB board depends on material quality, design accuracy, and strict production checks

- Local expertise supports consistency, speed, and accountability for complex electronics

- Design choices directly affect durability, heat control, and long-term performance

- A trusted manufacturing partner reduces risks as devices become smaller and more demanding

Introduction

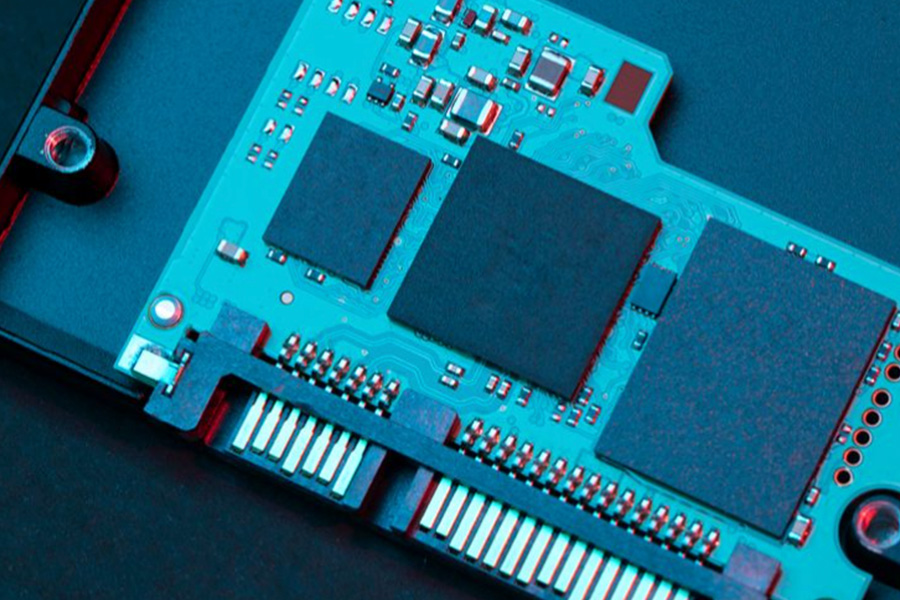

From smartphones and smart homes to medical devices and EV chargers, electronic products rely on one quiet hero. The printed circuit board. When a device works smoothly, rarely does anyone think about what sits underneath the casing. Yet reliability often lives there. A dependable board keeps signals clean, power steady, and components working together without drama.

As electronics become more compact and expectations rise, the demand for dependable PCB manufacturing in Singapore has grown. Local industries want boards that handle heat, vibration, and constant use, all while meeting tight timelines. So what actually makes a PCB board reliable in modern applications? It is not just one thing. It is a series of decisions, checks, and trade-offs that add up.

It Starts With the Materials, Not the Machine

A PCB board can look flawless and still fail early if the base materials fall short. Substrates, copper thickness, and surface finishes all play a role. FR-4 remains common, but higher-frequency or high-heat uses often need alternatives that cope better with stress.

In Singapore’s climate, humidity adds another layer of pressure. Materials must resist moisture absorption or performance drift over time. That is why many engineers sourcing a PCB board in Singapore look closely at material specs rather than headline prices. It is a small detail that avoids big headaches later.

Design Choices That Either Help or Hurt

Good manufacturing cannot rescue a poor design. Trace spacing, layer stack-ups, and grounding paths shape how a board behaves in real life. A layout that works in theory may struggle once heat builds up or signals interfere with each other.

Thinner, denser boards often seem more advanced. Yet reliability sometimes improves with slightly wider traces or extra clearance. The balance matters. Experienced teams involved in PCB manufacturing in Singapore tend to flag these trade-offs early, before a design reaches the factory floor.

Precision Matters More Than Speed

Fast turnaround is tempting, especially when product launches loom. Still, reliability thrives on control, not haste. Drilling accuracy, copper plating consistency, and solder mask alignment all affect how long a board lasts.

Modern facilities use automated optical inspection and electrical testing, but human judgment still plays a role. A trained eye can spot issues machines might miss. For companies sourcing a PCB board in Singapore, this mix of automation and expertise is often what separates dependable suppliers from risky ones.

Testing That Mirrors Real Use

A board that passes basic checks may still fail in the field. That is why stress testing has become more relevant. Thermal cycling, vibration tests, and electrical load simulations expose weaknesses early.

Think of it like testing a new car. A short drive proves it starts. A long journey shows whether it lasts. Reliable PCB manufacturing in Singapore often includes these extra steps, especially for industrial or medical electronics where failure is not an option.

Local Context Makes a Difference

Working with nearby manufacturers offers practical advantages. Communication is clearer, lead times are shorter, and design tweaks happen faster. There is also accountability. When issues arise, they are addressed directly, not buried in long email threads across time zones.

Singapore’s electronics ecosystem, supported by strong standards and skilled engineers, creates an environment where quality is expected, not negotiated. That context adds confidence when selecting a PCB board in Singapore for demanding applications.

Conclusion

A reliable PCB board is rarely the result of a single smart choice. It comes from solid materials, thoughtful design, careful production, and realistic testing. Each step supports the next. Skip one, and reliability slips.

As electronics continue to shrink while doing more, dependable boards become even more valuable. Businesses that invest in trusted PCB manufacturing in Singapore position their products for fewer failures and longer service life. To ensure your next project starts with a board you can rely on, contact MPN Tech to discuss your requirements and explore tailored manufacturing solutions.